About Us

Suzhou Desisen(DSS) Electronics Co.,Ltd

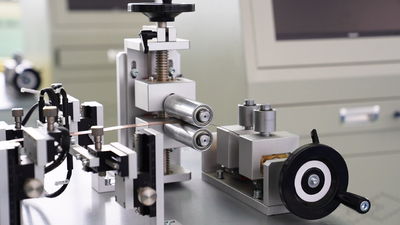

Suzhou Desisen (DSS) Electronics: Pioneering Non-Destructive Testing SolutionsAs a leading specialist in the research, development, and production of advanced non-destructive testing (NDT) systems, Suzhou Desisen (DSS) Electronics Co., Ltd.(苏州德斯森电子有限公司) delivers comprehensivedeliver comprehensive, fully automatic flaw detection solutions designed to enhance product quality, safety, and manufacturing efficiency for a global clientele.Our Core ExpertiseWe provide complete testing solutions, from ...