-

Automotive Parts Inspection

-

Bearing Defect Detection

-

Metal Pipe Bar Defect Inspection

-

Wire Rope Inspection

-

Sheet Metal Structural Profiles Inspection

-

Casting Crack Detection

-

Forging Quality Inspection

-

Eddy Current Flaw Detector

-

Ultrasonic Flaw Detector

-

Portable Eddy Current Flaw Detector

-

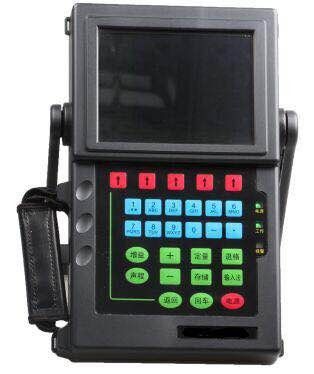

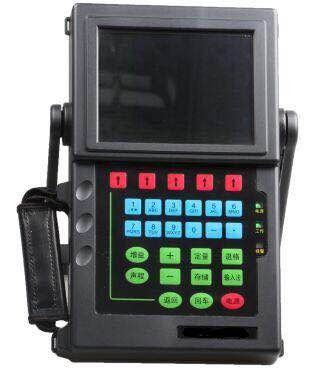

Portable Ultrasonic Flaw Detector

-

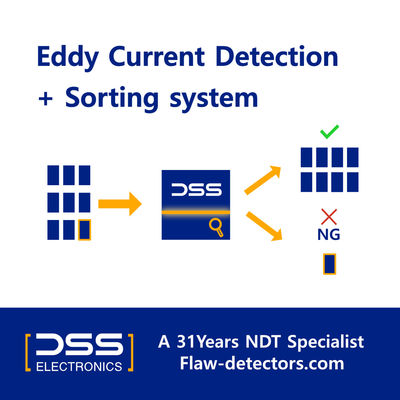

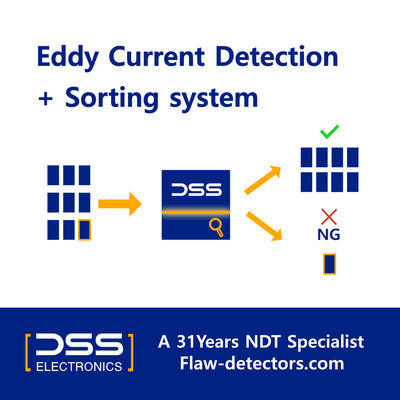

Eddy Current Sorter

-

Eddy Current Conductivity Meter

-

Ultrasonic Thickness Gauge

-

Magnetic Particle Flaw Detector

Ndt Digital Multi Channel Ultrasonic Flaw Detector HY-350

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Gain Range | 0-120dB In 0.1,2.0,6.0dB Steps | Dynamic Range | 30dB |

|---|---|---|---|

| Scanning Range | 0.5- 8000mm | Operating Modes | Single/dual, Penetration |

| Charger | 220~240V AC Input | Working Voltage | 7.4V± 0.3V |

| Size | 250*150*38mm | Weight | 1.28Kg |

| Highlight | 110dB Ultrasonic Flaw Detector,Digital Multi Channel Ultrasonic Flaw Detector,Ndt Ultrasonic Flaw Detector |

||

Product Description:

The ultrasonic flaw detection equipment is equipped with high-speed, bright large-screen colour LCD, which can work stably even under bright light, combined with one-button operation design, making the flaw detection process easy and fast; the equipment has built-in electronic manual, real-time prompts for operation steps and flaw detection methods, and it can also be triggered by one key for fast flaw detection, and synchronously and automatically test the zero point of the probe, the speed of sound and the K-value, which can assist the operator in precisely controlling the detection process. The equipment supports the production of DAC and AVG curves, with automatic gain and search memory of the highest wave function, can automatically display the defect echo position (including level, depth, distance, equivalent value), and through the freely adjustable door position, door width, door height of the automatic gate to achieve the sound and light alarm, but also automatically generate a standard flaw detection report, all-round protection of the professionalism and accuracy of the flaw detection work.

In terms of performance configuration, the equipment adopts imported original motherboard devices, equipped with high-capacity storage system, with 2000 pieces of flaw detection data space, to ensure that the data will not be lost after power failure; equipped with non-memory high-efficiency lithium batteries, to achieve more than 4 hours of continuous ultra-long working time, to meet the needs of high-intensity operations. In addition, the equipment built-in communication software, through the network cable directly connected to the computer can complete the flaw detection data printing and saving; support 50 groups of flaw detection channel free switching, the user is free to enter the industry flaw detection standards, and set the channel password, pre-stored exclusive flaw detection channel to prevent others from modifying; at the same time, with a bidirectional communication function, it is convenient for the user to edit their own personalised flaw detection report format, to fully adapt to the diversified business scenarios and user needs. user needs.

Application:

This instrument can detect internal defects (such as cracks, inclusions, porosity, etc.) and automatically locate, evaluate and diagnose them. It is widely used in testing laboratory, special inspection institute, shipbuilding, oil and gas equipment, aerospace, military, chemical industry, electric power, iron and steel, metallurgy, railway, automobile manufacturing, machinery, boiler and pressure vessel, special equipment, petroleum pipeline, construction industry, mould manufacturing and other industries. We have rich experience in flaw detection of forging, casting, plate, pipe, bar, steel pipe alloy parts; our customers are distributed all over the country, such as the State Special Inspection Institute, the National Steel Structure Inspection Centre, Shanghai Petroleum Machinery Manufacturing Company, Shanghai Wind Energy and Electric Power Company, Zhejiang BYD Automobile Manufacturer, China Railway Bureau, Xinjiang Petroleum Equipment Manufacturer and so on.

Technical Parameters:

| Name | Portable Ultrasonic Flaw Detector HY-350 |

|---|---|

| Display Ambient Temperature | -20~50℃ |

| Suppression | 0~99 Linear Suppression |

| Detection Mode | Half Wave/RF |

| Damping | 50/100/400Ω Auto Matching |

| Pulse generator | variable pulse generator |

| Sensitivity margin | >60dB |

| Resolution | >36dB |

| Horizontal Linearity | <1 |

| Vertical Linearity | <3 |

Support and Services:

2. The equipment into normal operation after the supply side will still be ready for the demand side to provide all the technical advice

3. In the use of equipment in the process of the demand side can not be resolved by the demand side of the technical problems, the supply side in the receipt of the demand side's request, should be answered and put forward solutions

FAQ:

A1: The brand name of this product is Desisen.

A2: The model number of this product is HY-350.

A3: This product is made in China.

A4: Yes, this product has ISO9001 certification.

A5: The minimum order quantity is 1.