-

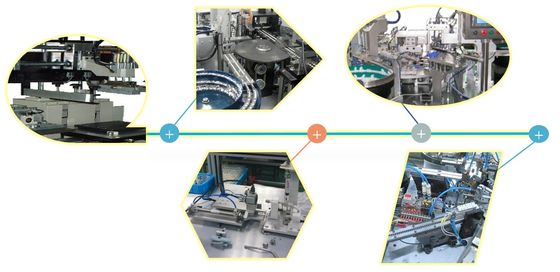

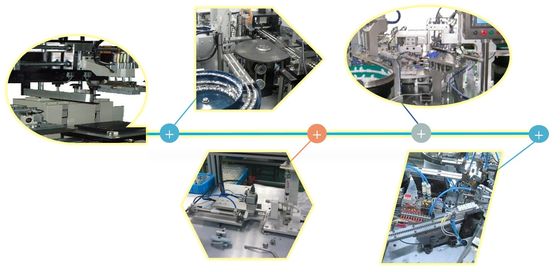

Automotive Parts Inspection

-

Bearing Defect Detection

-

Metal Pipe Bar Defect Inspection

-

Wire Rope Inspection

-

Sheet Metal Structural Profiles Inspection

-

Casting Crack Detection

-

Forging Quality Inspection

-

Eddy Current Flaw Detector

-

Ultrasonic Flaw Detector

-

Portable Eddy Current Flaw Detector

-

Portable Ultrasonic Flaw Detector

-

Eddy Current Sorter

-

Eddy Current Conductivity Meter

-

Ultrasonic Thickness Gauge

-

Magnetic Particle Flaw Detector

Intelligent Non-destructive Sorting Instrument ZGF-Ⅲ

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Applicable Conditions | The Same Size Of The Rules, Non-regular Pieces Can Be Applied. | Etection Speed | 1000-2000 / Hour (depending On The Size Of The Workpiece And The Operator's Proficiency) |

|---|---|---|---|

| Sorting Precision | Carbon: 0.03C B, Hardness: Brinell ± 10HB, Rockwell ± 1HRC C, Hardened Layer: 0.2mm. | Resolution A, Carbon | 0.01C B, Hardness: Brinell ± 1HB, Rockwell ± 0.1HRC C, Hardened Layer: 0.1mm. |

| Working Power | AC 220V ± 10V | External Dimensions And Weight | 364.1 × 191.6 × 300mm, 8kg |

| The Type Of External Probe | Sleeve Probe, Plane Probe, Pen Probe, Rectangular Probe. | ||

| Highlight | High Accuracy electrical conductivity tester,0.1ms/cm electrical conductivity tester,abs measure electrical conductivity |

||

Product Description:

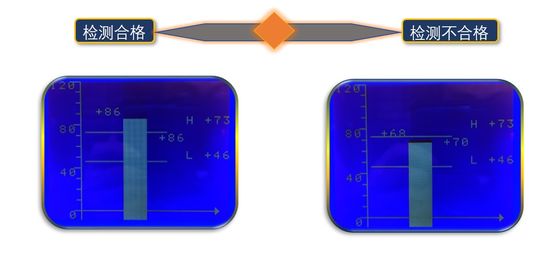

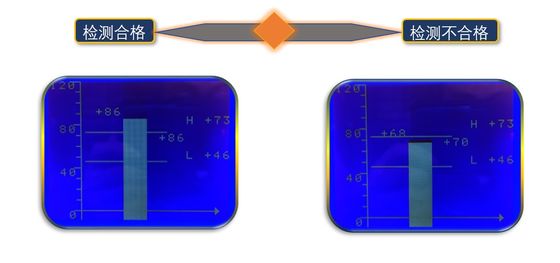

ZGF-Ⅲ intelligent nondestructive sorter adopts a large screen LCD display and a large specification digital display tube. The display interface includes: bar graph, cursor graph, waveform graph and digital display. Users can choose different display interfaces according to different sorting items, which makes the quality condition of the measured workpiece clear at a glance on the display and makes the operation of the instrument more intuitive and simpler for users.

1. Non-destructive testing, no special requirements on the surface of the workpiece (to avoid the traditional detection methods need to destroy the defects of the surface of the workpiece state).

2. The instrument is simple, convenient, with unqualified products sound and light alarm function (the instrument is set up within the man-machine dialogue function, only in the same specifications of the workpiece to prepare two standard samples and after a simple setup can be carried out after work).

3. Detection speed. (Detection of the workpiece only needs to be positioned to contact the appropriate probe can be, the efficiency of the traditional detection methods dozens of times, or even hundreds of times).

4. To meet the needs of large-volume workpiece inspection, to ensure product quality foolproof (workpiece can be a full 100 detection, to avoid the conventional sampling caused by the leakage of detection).

5. Instrument sensitivity can be adjusted in a wide range (detection current and frequency continuously adjustable to adapt to the needs of different workpieces and testing projects).

6. Rich graphical interface, the quality of the measured workpiece intuitive display (using liquid crystal screen display and digital tube dual display mode, the display interface has: bar graph, wave pattern, cursor map and digital display of four. According to the relevant graphics and cursor position can be observed intuitively the quality of the workpiece under test, after the relevant procedures can be set to measure the steel species, hardness value, hardened layer, carbon content, etc.).

7. The instrument is beautiful, light weight, AC and DC dual-use (instrument chassis using imported profiles, light weight, instrument built-in 12V maintenance-free rechargeable battery, suitable for work in the absence of AC power supply).

Technical Parameters:

| Features | Intelligent Non-destructive Sorting Instrument ZGF-Ⅲ |

|---|---|

| Working temperature | -15~55℃ |

| Saving temperature | -20~60℃ |

| Relative humidity | not exceed 85% |

| working voltage | AC220±10V/DC12V |

Applications:

1. Magnetically conductive materials (e.g. wire, plate, pipe, strip, billet and various automotive parts, standard parts, bearing parts, forgings, cast steel parts, etc.)

2. Distinguish between steel grades and identify steel grades of the same size material. (Material rapid sorting)

3. hardness testing and fast differentiation of workpieces of the same size. (Quick sorting of hardness)

4. Carbon content of materials can be measured for carbon structural steel. (Carbon fixing)

5. Distinction and identification of defects in materials and heat-treated workpieces. (Flaw detection)

6. Identification and sorting of mechanical properties of materials and heat-treated workpieces.

Support and Services:

1. From the date of completion of installation and commissioning of the equipment, as the beginning of the quality assurance period of the equipment. The supplier will warranty the equipment for one year and implement lifelong maintenance service for the equipment. In the equipment warranty period of the relevant costs borne by the supplier, in the equipment warranty period of the relevant costs of the supply side only charge material costs.

2. The equipment into normal operation after the supply side will still at any time for the demand side to provide all the technical advice

3. In the use of equipment in the process if the demand side can not be resolved on their own technical problems, the supply side in the receipt of the demand side of the request, we can carry out a virtual space conference, or as soon as possible to the scene.