Product Description:

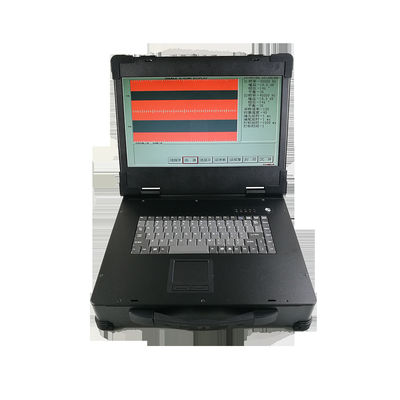

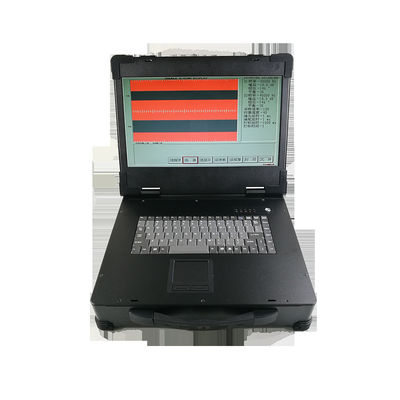

The Eddy Current Flaw Analyzer features an easy-to-read LCD display that provides real-time information about the material being tested. This display mode allows users to quickly and accurately identify any flaws or defects that may be present, making it an essential tool for quality control and inspection purposes.

With a detection range of 0.1mm-20mm and a detection accuracy of 0.01mm, the Eddy Current Imperfection Analyzer is capable of detecting even the smallest of imperfections. This makes it an ideal tool for testing a wide variety of materials, including metals, plastics, and composites.

In addition, the Eddy Current Flaw Detector comes with a 1-year warranty, ensuring that users can rely on it for years to come. The device is powered by AC220V, which makes it easy to use in a variety of settings and ensures that it is always ready to go when needed.

Features:

- Product Name: Eddy Current Flaw Detector

- Warranty: 1 Year

- Power Supply: AC220V

- Detection Range: 0.1mm-20mm

- Working Environment: Temperature: -10℃~50℃, Humidity: ≤85%RH

- Eddy Current Imperfection Analyzer

- Eddy Current Defect Detector

- Eddy Current Imperfection Analyzer

Technical Parameters:

| Detection Speed |

0.1s |

| Detection Accuracy |

0.01mm |

| Working Environment |

Temperature: -10℃~50℃, Humidity: ≤85%RH |

| Data Storage |

128GB |

| Data Transmission |

USB, WIFI |

| Display Mode |

LCD |

| Detection Principle |

Eddy Current |

| Detection Range |

0.1mm-20mm |

| Power Supply |

AC220V |

| Warranty |

1 Year |

This is the technical parameter table for the Eddy Current Defect Detector, also known as Eddy Current Imperfection Detector or Eddy Current Defect Analyzer.

Applications:

The FET-9HS is an advanced eddy current detector that is capable of detecting surface and subsurface cracks, corrosion, and other defects in metal components. It is equipped with a high-speed detection system that can detect defects in just 0.1 seconds, making it a highly efficient tool for quality control and inspection.

The FET-9HS is designed for use in a variety of applications and scenarios. It can be used to detect defects in aircraft parts, such as engine components, landing gear, and airframes. It can also be used to inspect automotive components, such as engine blocks, transmission gears, and suspension systems. In the manufacturing industry, it can be used to inspect metal parts such as pipes, tanks, and pressure vessels.

The FET-9HS is manufactured in China and is ISO9001 certified, ensuring that it meets the highest standards of quality and performance. The minimum order quantity for this product is 1, and the price is discussed personally. The product is packaged in a wooden box for safe transportation and has a delivery time of 20-30 work days.

The FET-9HS has a variety of features that make it a versatile and efficient tool for defect detection. It has an LCD display mode that provides clear and easy-to-read results, and data can be transmitted via USB or WIFI for easy analysis. The product also has a large data storage capacity of 128GB, ensuring that all test results are securely stored for future reference.

The FET-9HS has a supply ability of 100 units and comes with a 1-year warranty, ensuring that customers can rely on this product for accurate and reliable defect detection. Payment terms for this product include T/T and D/P, providing customers with flexible payment options.

In summary, the Desisen FET-9HS Eddy Current Flaw Detector is an advanced eddy current detector that is widely used in various industries for quality control and inspection. It is a highly efficient tool for detecting defects in metal components, and its versatile features make it a valuable asset for any business.

Customization:

Customize your Desisen FET-9HS Eddy Current Imperfection Analyzer to meet your specific needs with our product customization services.

Our product is made in China and comes with ISO9001 certification. The minimum order quantity is 1 and pricing will be discussed personally. Packaging details include a sturdy wooden box to ensure safe delivery. Delivery time is typically 20-30 work days.

Payment terms accepted include T/T and D/P, and our supply ability is 100 units. The detection speed is an impressive 0.1s and the detection accuracy is 0.01mm. Data transmission options include USB and WIFI.

Our Eddy Current Imperfection Analyzer is a reliable tool to detect defects in various materials. It comes with a 1-year warranty and can operate in environments with temperatures ranging from -10℃ to 50℃ and humidity levels of ≤85%RH.

Customize your Eddy Current Imperfection Detector to meet your specific needs with Desisen's product customization services.

Support and Services:

The Eddy Current Flaw Detector product is a non-destructive testing tool used to detect surface and sub-surface defects in conductive materials. Our product technical support and services include:

- Expert technical assistance for setup, operation, and troubleshooting

- Customized training for operators and technicians

- Calibration and repair services

- Software upgrades and updates

- Access to a comprehensive library of resources, including manuals, guides, and FAQs

We are committed to providing our customers with the highest level of support and service to ensure the optimal performance of their Eddy Current Flaw Detector product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!